Typical Value①

| Grade |

Purity |

B2O3 |

Tot. Oxygen |

Avg. Particle Size (D50) |

Crystal Size |

Tap Density |

Surface Area (BET) |

| HSL |

99.4% |

0.05% |

0.4% |

35 µm |

35 µm |

0.6 g/cm3 |

2 m2/g |

| HS |

99.4% |

0.05% |

0.4% |

20 µm |

20 µm |

0.6 g/cm3 |

2 m2/g |

① Values represent typical data and will vary within ranges established for a particular grade

Applications

★ As additive for polymers such as PA and PE to increase thermal conductivity

★ As additive for thermal interface materials to enhance the thermal conductivity

★ As additive to color cosmetics, to enhance skin feel and optical pearl effect

★ As raw material for high temperature insulation composite material

★ As additive to premium lubricant oil

★ As release agent in optical glass production process

Characteristics

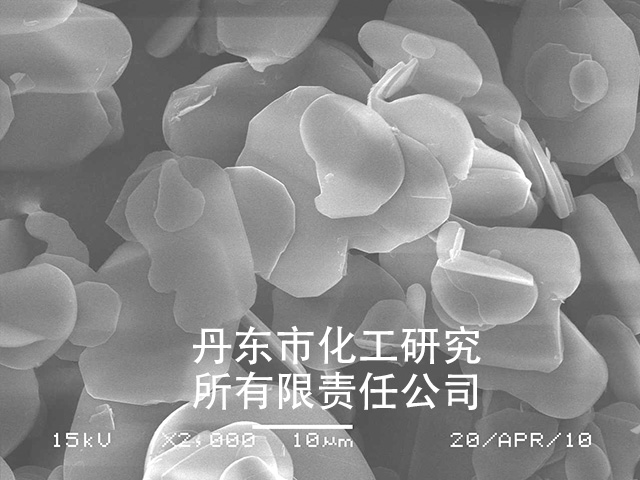

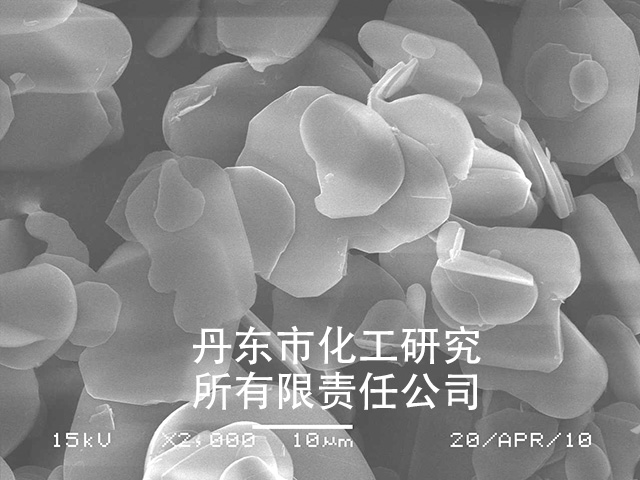

These two grades are produced at temperatures up to 2,100°C. They have single platelet microstructure and high crystallinity. Due to the process control, the crystals grow significantly which results in large platelet size. Those powders are equivalent to the products available in the market place.

Over the last couple of years the density of electronic packaging has increased significantly. Due to the miniaturization and the elevation of the specific power the electronic components are faced with high thermal energy output. This requires the development of thermal conductivity polymers. Very good examples are LED, small electronic terminal equipment and automotive engine control units as well as battery technology. Base Polymers typically used in those applications offer thermal conductivities in the range of 0.1 to 0.4 W/mK. In order to adjust the thermal conductivity of a polymer, functional fillers have to be added. Boron Nitride is the perfect choice, since it offers the highest levels of thermal conductivity (400W/mK) of any other dielectric and non-toxic filler. Resulting compounds with Grade HSL and HS can reach levels over 10 W/mK depending on the loading and the morphology of the Boron Nitride powder.

High crystallinity h-BN typically allows higher thermal conductivity, electrical insulation, lubricity, high temperature resistance and anti-corrosion against melting metal than common products. They can be used in any kinds of high-end field which cosmetics and thermal conductivity application are included.